The Ladle Monitoring System provides an accurate and reliable measurement solution to ensure plant safety and help set maintenance schedules in the steel plants across the world.

- Ladle Life

- Benefits

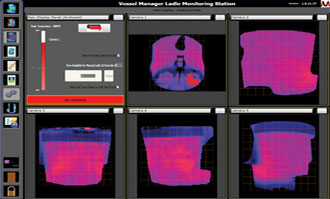

Ladle Recognition :

The software features integrated intelligent shape recognition technology which is configured to identify all the ladle profiles used in plant whilst excluding other elements. This system ensures false alarms are not reported as a result of hot background objects. Data capture and analysis starts once the software has confirmed the presence of a ladle in the camera's field of view.

Ladle Identification :

Vessel Manager stores the temperature data for each individual ladle on plant for long term analysis and trending. The ladle id comes from ladle tracking system and based on ladle id, the temperature data from each thermal imaging camera is analysed.

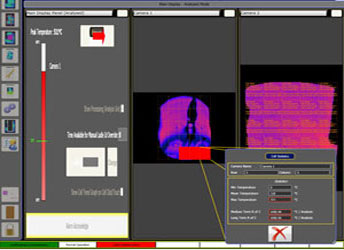

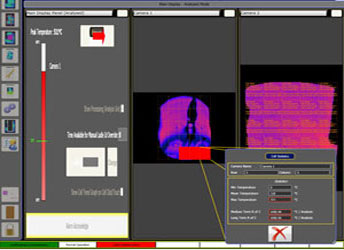

Ladle Analysis :

Ladle Monitoring System features a fully configurable analysis system, allowing a grid to be overlaid on the thermal images. Each cell in the grid provides the min/max/mean temperature for that area, along with rates of change, position and camera id. The live temperature data from each cell is compared with pre-configured alarm thresholds - any discrepancy between the live data and the predefined limits will raise an alarm. The software's on-screen analysis grid clearly highlights the location of the alarm, giving the operator immediate indication of a potential problem.

- Improved safety

- Prevention of break-outs

- Extended lifetime of ladle refectories

- Evaluation of different refectories

- Detection of problematic areas

- Cast refractory uniformity