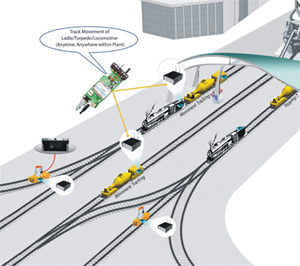

Torpedo and Ladle Tracking System on Railway - torpedoAPP aims to improve coordination and efficiency among Blast Furnaces, Steel Making Shops and Repairing Shops. The torpedo and ladles in steel plants serve as capacity buffers of hot metal to the balst furnaces and as feed buffers of hot metal to the steel making shops. Efficient co-ordination of torpedo and ladle is of paramount importance to any steel plant for minimizing hot metal dumping and ensuring optimum supply of hot metal to the steel making shops.

torpedoAPP provides accurate and detailed treacking of tropedo and ladles, informing their exact position, weight and status, registering their idle time, informing causes of dealy and keeping exact contact times with hot metal. The system also continuously monitors the position of the locomotives and detects the connection (of diconnection) of the locomotives with torpedo and ladle anywhere across the steel plant.

- Features

- Benefits

- Online tracking of Torpedo/Ladle position. weight and status

- Travel time and other Torpedo/Ladle movement statistics

- Plant Mimic with Graphical Torpedo/Ladle Movements

- Keep track of relationship between Torpedo/Ladle Heat Processes (production information required)

- System predicts the Torpedo/Ladle re-lining schedule based on tare weight and Torpedo/Ladle condition.

- Online consumption of hot metal at steel making shops.

- Provide information for Reports such as "ladle times", "Empty Times", "Average Travel Times" etc.

- A complete visibility

- Minimize idle time

- Energy Saving

- Increase scheduling efficiency

- Increase transport efficiency

- Maintenance savings

- Equipment protection

- Better production forecast

- Torpedo/Ladle breakage prevention